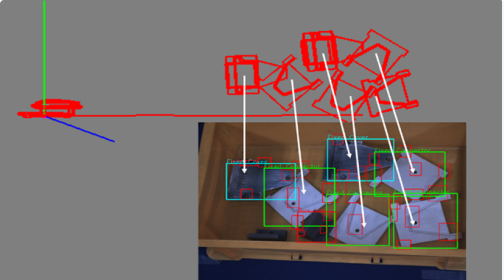

Bin Picking & Packing

For various industrial parts randomly placed inside a box, our system performs 2D image-based object recognition and segmentation. Each identified object is then matched with its corresponding 3D point cloud to estimate its precise 6D pose (position and orientation). Based on the estimated 6D pose information, workspace modeling is performed, and the resulting data are directly utilized for robot-based automation tasks.

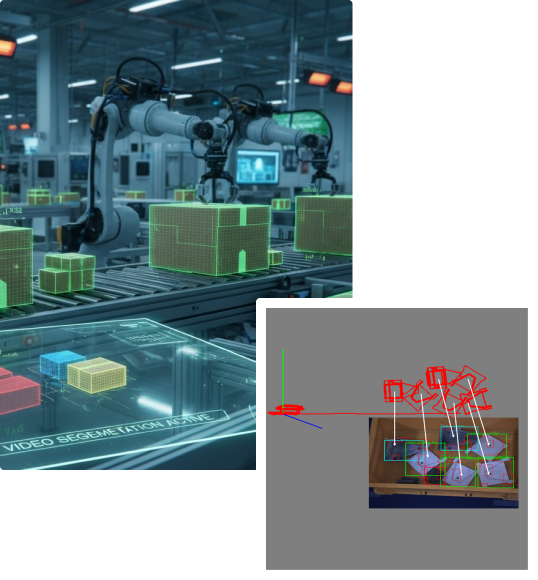

Conveyor Belt Environment

In industrial settings, our system performs real-time recognition and segmentation of metallic components moving along conveyor belts. Integrated with our High-Precision 3D Camera System, the solution intelligently detects each object’s regions of interest (RoI) and relays this information to the 3D camera, enabling even more accurate 3D measurement. Furthermore, by analyzing the segmented and measured 3D data, the system can conduct defect detection and quality inspection with high precision.